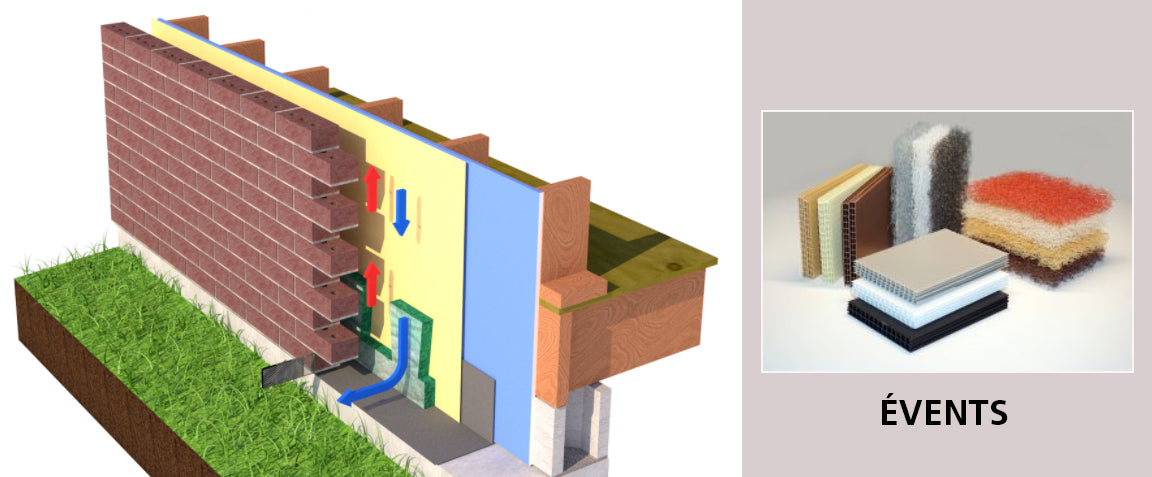

In masonry cavity walls, collection of mortar behind facings, flashing levels and weep holes is essential for good wall performance and to prevent water damage. Mortanet and WallDefender products work to protect masonry against moisture damage by preventing mortar deposits from clogging weep holes. Its 90% open mesh allows moisture to flow to the openings and air to move into the cavities to promote drying. Finally, the components of the products are compressible to allow variations in cavity width during installation and allow air circulation by equalizing the pressure.

Be aware, however, that there is one more component in the Mortarnet product. The wicking net of the latter is covered with an additional membrane that prevents insects from settling.

Available in several thicknesses such as: 0.4'', 1'' or 2'' of air space in boxes of 100 linear feet.

VENTS

In addition to the existence of these two devices in order to make our construction efficient, the National Building Code prescribes the installation of evacuation vents at a maximum of 800 mm (therefore +/- 30'') directly on the flashing at the bottom of the wall, above the finished floor. But, what may be new to some is that now it is becoming more common to also place exhaust vents at the top of the wall, i.e. just below the facade and soffit of a building. a building. The reason is one of drying and ventilation. As the air in the cavity warms up during the day due to the degree of sunlight hitting the facade, the moisture in the cavity tends to change from water droplet to vapor during the evaporation process.